Original Kitchen And Bathroom Industry Mainstream Media Kitchen And Bathroom News

Supply chain disruptions continue to have a serious impact on material prices, backlogs hua, utu uta me nga huringa kaupapa kihini me te kaukau, according to U.S. media reports. Ahakoa he rangitahi pea te ahuatanga o naianei, it is estimated that the situation will continue into next year.

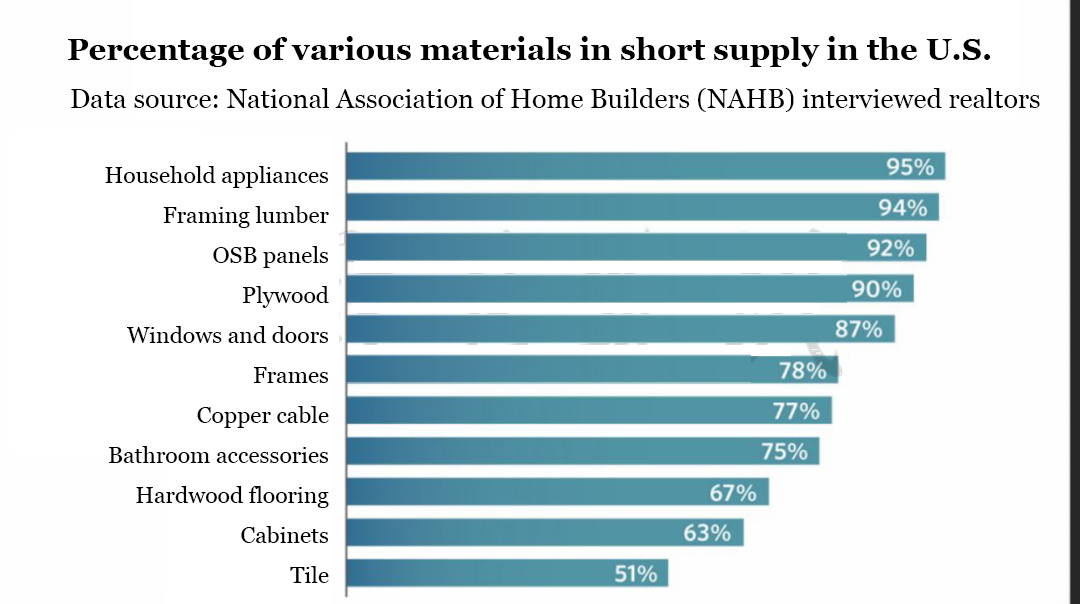

E ai ki te rangahau hou a te National Association of Home Builders (NAHB), the situation has worsened significantly “tino nui” since this time last year. The impact is broader, including bathroom accessories, taputapu whare, tile, cabinets, and other key components for manufacturing refrigerators, nga umu, horoi rihi, ngaruiti, washers and dryers are in short supply. Among the realtors surveyed, the shortage of bathroom accessories reached 75 ōrau. Tile reached 51 ōrau. The most serious is household appliances, which reached 95 ōrau.

The current shortage of materials is having a wider and deeper impact than at any time since 1990, and rising costs are exacerbating this effect, causing builders’ confidence in the market to fall to its lowest level in a year.

Ko nga kaiwhakarato kaukau, nga whakapaipai whare, kai tohatoha, realtors and others are facing a year-long “storm” o te piki haere o te hiahia, apitihia ki te kore rawa o te rawa, wero logistical me te mate urutomo. While remodeling demand is soaring with increased vaccination rates and a DIY market for homes spawned by emerging lifestyles, na te korenga o nga mekameka tuku, na te ngoikore o nga hua hanga whare. I tenei wa, supply constraints have caused material costs to soar.

E ai ki nga korero hou mo te Maakete mo te Kitchen and Bath (a muri ake nei: KBMI, te U.S. Kitchen and Bath Market Index) i whakaemihia e te National Kitchen and Bath Products Association (NKBA), John Burns Kaitohutohu Taonga Rawa, supply chain issues coupled with rising material prices and transportation costs are forcing an increasing number of home design firms to face longer lead times while needing to seek alternative sources of supply and raise prices to protect profit margins.

E ai ki te KBMI, te U.S. Taurangi Maakete Kihini me te Pati mo te hauwhā tuatahi o 2021, 45 percent of dealers and designers surveyed said material shortages and product pricing are impacting project lead times. 60 percent of manufacturing facilities surveyed noted average lead times of six weeks or more, he nui te pikinga mai i te hauwhā o mua. Capacity is being severely constrained by longer raw material lead times and significant freight delays. I tenei wa, 67 percent of realtors surveyed noted that projects have been backlogged for more than three months. And 21% of realtors noted that the backlog will continue until the end of 2021.

I tenei wa, U.S.-based factories are beginning to add capacity and adjust their supply chains. According to reports, in June this year, te U.S. DEVIDA bathroom announced that it will “kaupapa matua” the production of certain brands of products, while suspending production of other series. The company said that this situation is expected to continue until the fourth quarter of 2021. They also noted that while no new orders will be accepted during this period, existing orders are not affected by the decision.

In addition to the United States, Kei te anga ano a Tiamana ki te raru whakararu o nga mekameka tuku. Germany’s Bavarian plumbing and bathroom industry from wood, plastic, steel, brass has also been shortages. I roto noa i te tau kotahi, the price of insulation board has increased by 10%. Flat glass has decreased by 15 ōrau, steel has risen by 30 ōrau, and roofing panels have increased by 31 ōrau. And the global price of copper has risen 80 percent in the past 12 marama.

In addition to delivery issues, kei te raru ano te ngoikore o nga kaimahi mohio ki te umanga hanga. Te kimi kaimahi mohio, tae atu ki Haina, kua waiho hei tino uaua ki te kimi kaimahi.

iVIGA Tap Factory Kaiwhakarato

iVIGA Tap Factory Kaiwhakarato