Original köks- och badrumsindustri Mainstream Media Köks- och badrumsinformation

In the afternoon of July 28, med temat “meet 5G, intelligent manufacturing”, “2021 China ceramic and sanitary digital manufacturing forum” was held in Guangzhou Ceramic Industry Exhibition. It was co-sponsored by China Ceramic Industry Association, Kök & Badrumsinformation, Ceramic Information, TaoWei.com, Guangdong New Union Exhibition Service Company, and co-sponsored by China Industrial Cooperation Association Home Decoration Branch. Wang Fushun, Chief Engineer of Tangshan He Xiang Intelligent Technology Co., Ltd. delivered a keynote speech on “Intelligent and Digital Sanitary Ware Factory R&D and Application” at the forum.

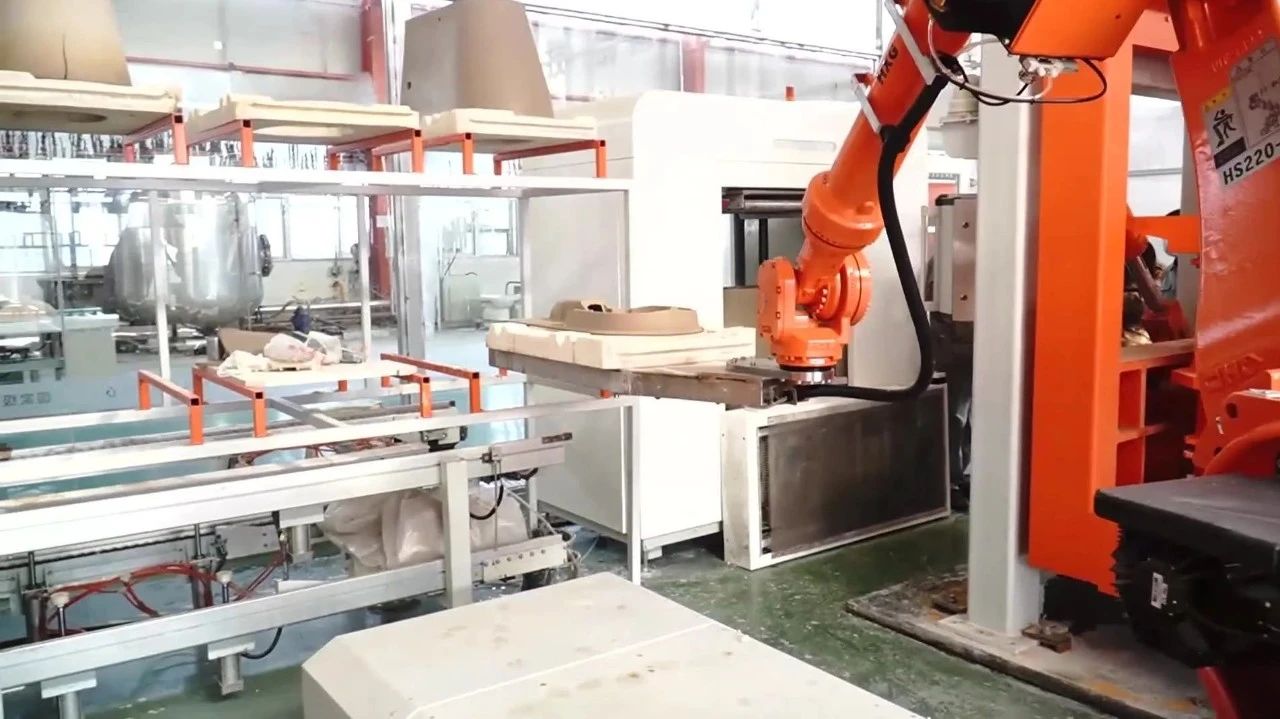

The development of China’s sanitary ware factory equipment has been progressing. Sanitary ware factories are tending to be automated and intelligent, and individual factories have achieved less humanization and will even realize unmanned production in the future. The digitalization and transparency of production, equipment, energy consumption and efficiency of sanitary ware factories is the general trend. As the leader of high-end sanitary equipment in China, He Xiang’s high-pressure grouting equipment market share has reached more than 80%, making an important contribution to the development of China’s sanitary factories in terms of intelligence, digitization, energy saving and environmental protection.

For the development trend of intelligent and digital sanitary ware factory, Wang Fushun believes that to achieve this goal, “human”, “machine”, “material”, ” Law”, “link” five elements must be lean and intelligent direction. According to his years of experience in the analysis, he believes that to achieve this goal, the main equipment of sanitary production must be innovative in structure and process development, especially the sanitary ceramics molding, repair, handling, spraying links.

The intelligence and digitalization of sanitary equipment must be efficient and easy to use as a prerequisite. Wang Fushun shared with high-pressure molding machine and robot glazing as a case study. In terms of advanced high-pressure molding machine, He Xiang’s overall design idea is to use valve islands, which are connected to a large number of air tubes and controlled automatically by a bus. The power and control lines are controlled separately. This design idea helps to reduce mutual interference, improve the usage rate of the bathroom equipment and reduce the failure rate of the equipment. He Xiang’s intelligent high-pressure molding machine also realizes intelligent detection. Once any problem occurs during the operation of the equipment, it will be automatically fed back to the system to realize intelligent monitoring.

Herxiang’s robot glazing equipment is also at the forefront of the industry, supporting the mixing of multiple species on the blank. It has a split-seat spraying time of 180 sekunder. The handling robot has a handling cycle of 45 seconds under mixed handling mode conditions. This has been widely used in the automated production of sanitary ceramics in sanitary ware enterprises.

Creating intelligent, digital sanitary ware factory, can not be separated from the digital, transparent information system. According to Wang Fushun, the information system created by He Xiang mainly contains data acquisition system, equipment management system, mold management system, quality management system, electronic work instructions, and electronic Kanban system.

1

Data collection system

The system contains three major data: Först, the basic data. Second is the product data. Third is the expansion data. The basic data needs to collect a large number of equipment status, process nodes, action nodes, model information and other key data entered into the system. Product data is used according to some functions with barcode electronic instructions. This is mainly used for the traceability of the whole life cycle of the product. The product center is the data collected in real time and monitored in real time, and compared with the data of the public system. Expanded data is mainly for energy consumption statistics, cost accounting, quality improvement, process improvement and other functions to provide data support.

2

Equipment management system

This system contains maintenance and equipment warning. The main feature of the equipment maintenance system independently developed by He Xiang is that the maintenance management plan will be automatically generated after the equipment ledger is entered into the system. The equipment alarm includes equipment warning and product-related warning, and the automatic alarm of the equipment is mainly based on the data collected in real time.

3

Mold management system

There are manual management and online management for mold management. The manual management method is to compare and enter the basic performance data of the mold and the performance data after each maintenance. When the mold performance data is lower than the preset performance data, it generates an early warning or reminds to go offline for maintenance. The online management method is to compare and enter the basic mold performance data and collect the mold performance data in real time. When the mold performance curve is lower than the preset performance curve, it generates an early warning or reminds to go offline for maintenance.

4

Quality Management System

Quality management system includes quality statistics, quality traceability and quality analysis. The system can assist sanitary ware enterprise managers to significantly improve product quality.

5

Electronic operation instruction

This is the operation instruction. It can be displayed in a variety of ways to be able to, such as through the PDA, cell phone terminal, touch screen computer. And for cell phone terminals, bathroom business managers wherever they go, they can query at any time and anywhere.

6

Electronic signage system

Electronic Kanban system can present real-time product yield, quality and order execution, which can be displayed in all corners of the workshop. Cell phones and tablet PCs, data terminals can be checked at any time. This system can be implemented when building a new factory or renovating an old one. Intelligence is achieved through major equipment and major production workshops. This system can connect the intelligent system of each workshop to achieve the overall intelligence.

As the leader of high-end sanitary equipment, He Xiang’s innovative development has accelerated the development process of the sanitary industry towards intelligence and digitalization. 2021 China Ceramic and Sanitary Digital Manufacturing Forum decided to award He Xiang the honor of “Intelligent Manufacturing Equipment Benchmark Enterprise in the Ceramic and Sanitary Industry” in recognition of He Xiang’s healthy development and outstanding contribution to the sanitary industry.

iVIGA Tap Factory Supplier

iVIGA Tap Factory Supplier