Bathroom Industry Platform

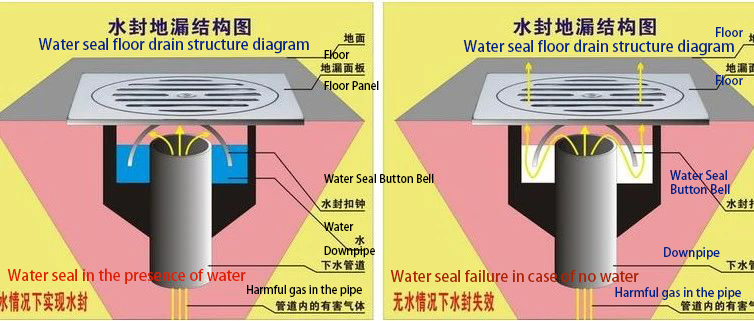

Floor drain is an important interface connecting the drainage system and indoor floor in the residence. The quality of floor drain directly affects the indoor air quality, because the drainage pipe and septic tank of floor drain are connected to the living space, and the old floor drain relies on water storage to form a water seal to separate the living space from the piping system. If the water seal of the floor drain loses its function or the seal of the floor drain which has no water seal is not closed tightly, there is no barrier between the sewer and the indoor space, and the odor and toxic and harmful gases in the sewer will overflow along the pipe and be distributed in the living room.

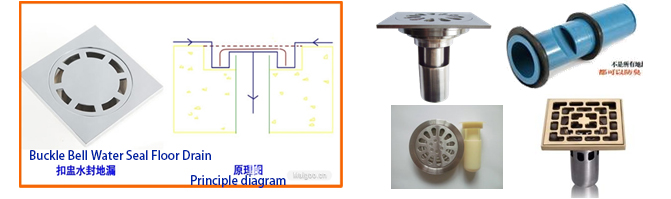

The structure of traditional water seal floor drain is bell-type, like a buckle bowl structure buckled on the downspout, forming a “U” type water storage bend, using the “water seal” in the water storage bend to achieve the sealing effect.

The principle and structure of traditional water seal floor drain (Figure 1)

Structure diagram of steel water seal floor drain (Figure 2)

Most water-sealed floor drains have shallow water seal and too little water seal, which will dry up and return to odor because of time and dry weather. Além disso, the deeper the water seal height is, the more it will affect the drainage speed and deposit dirt more seriously, which is difficult to clean.

Water seal floor drain principle structure diagram (Figure 3)

Eccentric block type of sealed floor drain, aquilo é, with a gasket, one side is fixed with a pin, using the principle of gravity eccentricity to seal. In doing so, one is not tightly closed, and the other is that the pin is easily damaged, resulting in failure.

Eccentric block seal floor drain principle structure diagram (Figure 4)

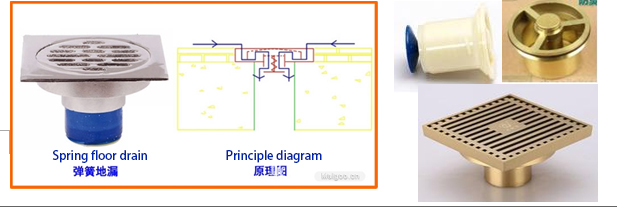

Spring type sealed floor drain is divided into upper and lower spring type. The upper spring type is to press the cover plate, the cover plate will pop up, press it again, and it will be reset. The lower pop-up type is sealed by stretching the gasket at the lower end of the seal core with a spring. Since the spring is made of boron iron, it is easy to rust and the elasticity gradually decreases until it fails. The life is not long, and the spring is easy to wind up hair and fabric, which is not easy to clean.

Spring-type sealed floor drain principle structure diagram (Figure 5)

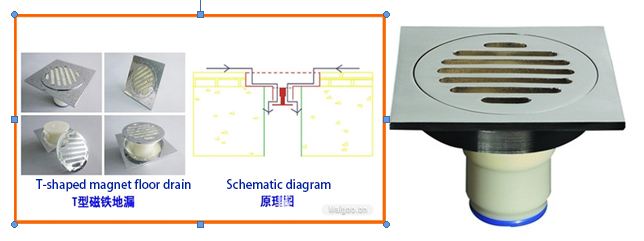

Suction stone type sealed floor drain is sealed with the magnetic force of two magnets to absorb the gasket. Due to the poor quality of ground water, such as washing items, brushing the floor and various other reasons, the sewage will contain some iron impurities adsorbed on the iron-absorbing stone. After a period of time, the layer of impurities will cause the gasket to fail to close. Além disso, the magnetic force will gradually decay due to the earth’s large magnetic field.

Principle structure diagram of suction stone type sealing floor drain (Figure 6)

Silicone type sealed floor drain uses two pieces of silicone to seal. Drainage process dirt is left at the two silicone sheets to form a gap, and the odor runs out, unless you clean it every day. The effect of overflow prevention, insect prevention and life span are not very good.

Silicone type sealed floor drain principle structure diagram (Figure 7)

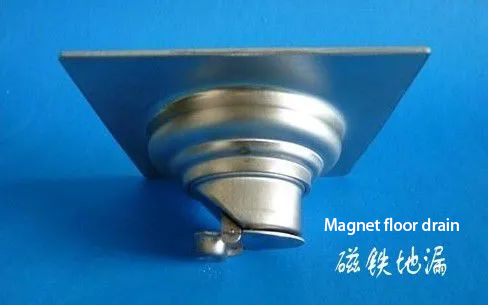

Magnet type sealed floor drain

Magnet floor drain is a floor drain device that uses the gravity balance principle of permanent magnet to open and close by braking up and down. Through the precise calculation of gravity and magnetic force and clever design of the structure, it makes the gasket open freely and realize automatic sealing. When water flows into the floor drain, the gravity of the water will open the ABS gasket at the bottom when it reaches a certain amount, and the water will flow freely. After the flow of water is interrupted, the ABS gasket will be closed automatically due to the magnetic force, and it will be completely sealed so that the gas, pests and overflow water in the pipe cannot go up.

Magnet type sealed floor drain (Figure 8)

No entanto, for various reasons such as water quality and ground cleaning, some ferrous impurities will be adsorbed between the two magnets and gradually accumulate, which will cause the two magnets to be unable to completely absorb each other. The gasket will also not be completely sealed, and in addition the magnet in the sewage is not as stable as in the air. The effect of the earth’s large magnetic field will also make the magnetic force gradually weaken, so the performance is not very stable.

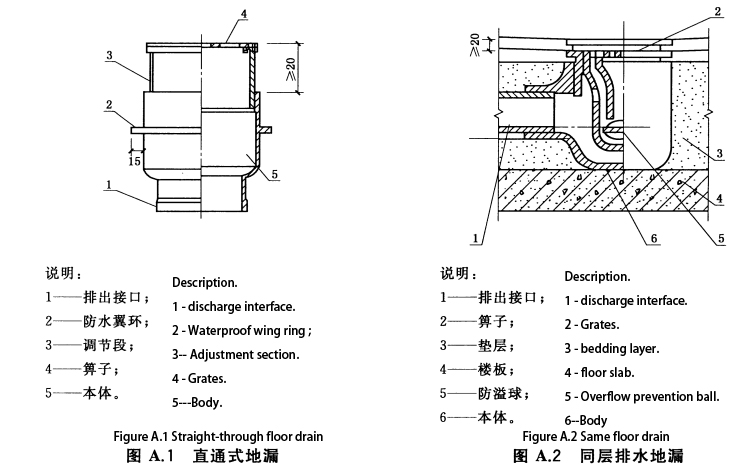

Various floor drain profiles: CJ∕T 186-2018 Floor drain

Classification of floor drains:CJ∕T 186-2018 Floor drains

3 Terminology and Definitions

The following terms and definitions apply to this document.

3.1

floor drain

A device that removes water from the floor or simultaneously accepts drainage from appliances. It consists of grates, body, drainage interface and other components.

3.2

water seal

The water storage structure used to block the escape of harmful gases in the floor drain.

3.3

Straight floor drain

The body does not have water seal or other accessories for the floor drain of the lower vent.

CJ/T 186-2018

3.4

water seal floor drain

Specifically refers to the internal water seal with water storage bend or other construction type, to meet the effective water seal depth, minimum water seal capacity and water seal ratio of the floor drain.

3.5

special type floor drain

Non-through floor drain with one or more functions. Such as anti-dry floor drain, water injection floor drain, closed floor drain, net frame floor drain, anti-reflow floor drain, multi-channel floor drain, side-wall floor drain, same level drainage floor drain, anti-siphon floor drain, high flow special floor drain, etc..

3.6

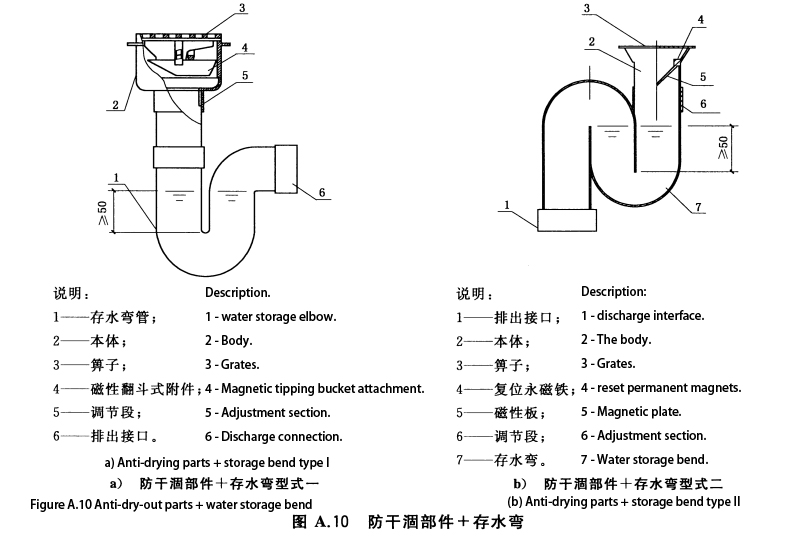

anti-dried up floor drain

Water-sealed floor drain with the function of preventing the water seal of the floor drain from drying up (water seal evaporation, etc.).

3.7

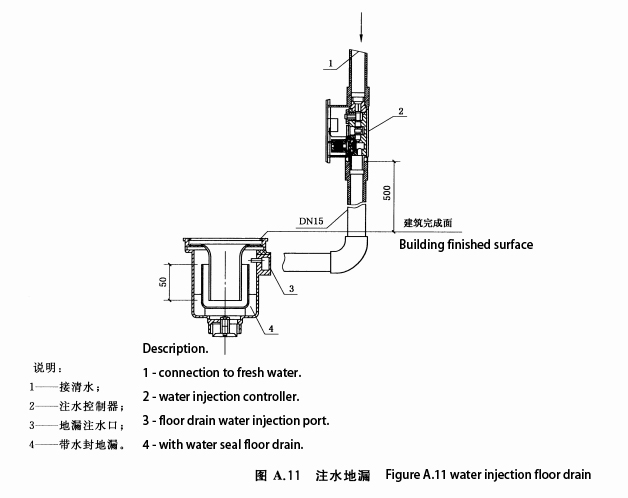

water injection floor drain

The floor drain that can maintain a certain depth of water seal by injecting water into the water storage bend through the water injection controller.

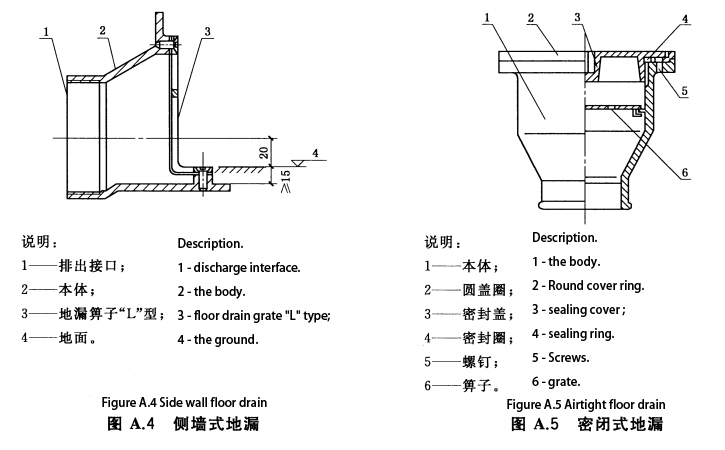

3.8

Seal-type floor drain

A floor drain with a sealed cover. The floor drain without water seal that is opened by hand when draining and closed when not draining.

3.9

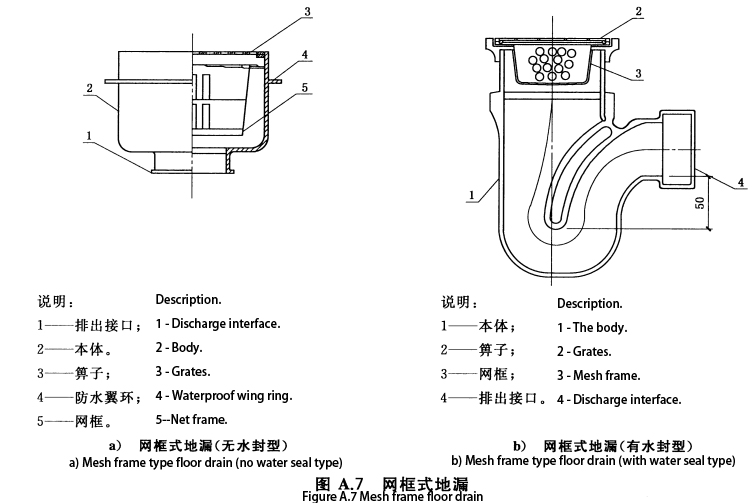

Grid-type floor drain

A floor drain with a movable grid frame to intercept debris in water, and its internal structure is divided into two types: with and without water seal.

3.10

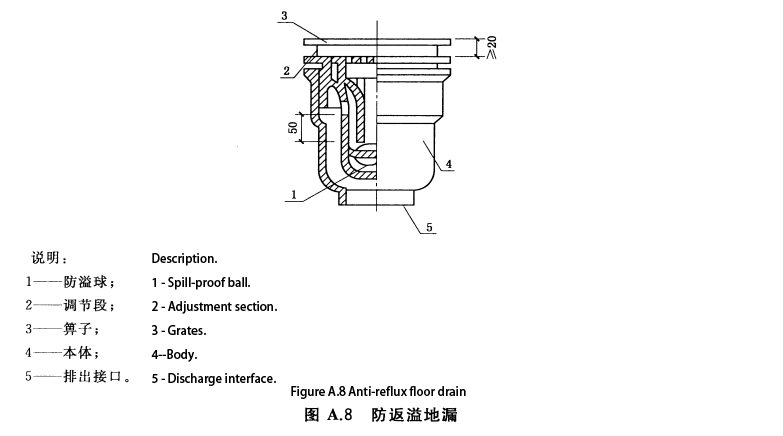

forbidden-spill floor drain

It has the function of preventing wastewater from overflowing to the ground when discharging, and also has the function of preventing wastewater from overflowing to the ground in the drainage system.

3.11

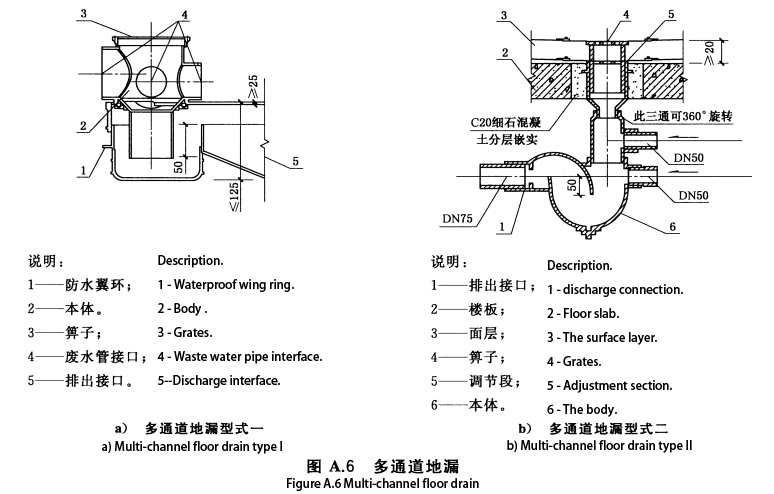

Multiple connection floor drain

Water-sealed floor drain that simultaneously accepts ground drainage and 1~2 appliance drainage.

3.12

Side-drain floor drain

The grate is “L” type, installed in vertical direction, and has the function of accepting and excluding water on the ground in a lateral direction without water seal.

3.13

Embedded floor drain

It is installed directly in the bedding layer, and the discharge pipe does not cross the floor with water seal floor drain, also called direct buried floor drain.

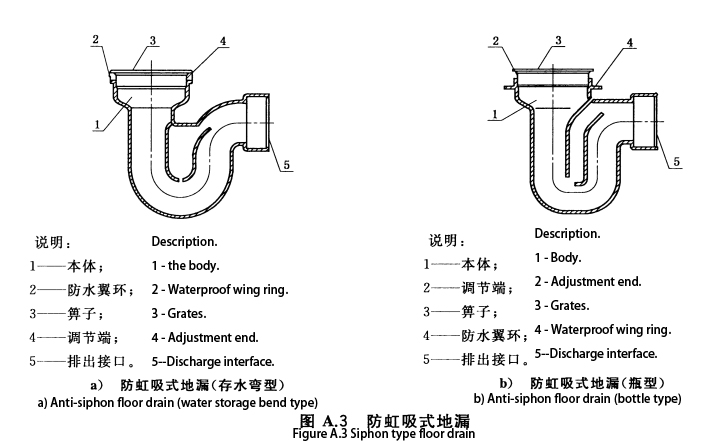

3.14

Anti-siphon floor drain

A water-sealed floor drain that prevents negative pressure suction and reduces the loss of siphon water seal.

3.15

special large flow floor drain

Watertight floor drain with large grate opening area to accept large drainage flow.

3.16

Seal capacity

The volume of water storage in the range below the water seal.

3.17

Mechanical anti-dry unit

Set in the floor drain body with slow evaporation loss of the water seal, and has the role of overflow prevention mechanical parts, such as floating ball type or live plate type anti-dry parts, magnetic bucket anti-dry parts, etc..

3.18

grate

Floor drain component parts, installed in the floor drain surface with pore cover.

3.19

cover

It is a component of closed floor drain and is installed on the cover surface without a hole on the surface of the floor drain.

3.20

adjustable segment

The component part of floor drain, adjusting the height of the calculating surface in harmony with the surface of the floor.

3.21

waterproof wing ring

It is a part of the floor drain body and is set around the floor drain body to prevent water seepage from the contact part of the floor drain and the flooring.

3.22

Seal depth

The vertical distance between the highest water surface of water stored in the floor drain and the lower port of the water seal.

3.23

Ratio of water seal

The ratio of the free water surface area between the outlet end of the water seal of the floor drain and the inlet end of the channel.

3.24

Self-c!eansing capacity

The internal structure of the floor drain has the ability to prevent the deposition of debris, and the discharge rate of 100 small plastic balls is usually used under the rated drainage flow.

The self-cleaning capacity is usually measured by the discharge rate of 100 small plastic balls under the rated drainage flow.

Fornecedor de fábrica de torneiras iVIGA

Fornecedor de fábrica de torneiras iVIGA