Smart Toilet muaj 8.5% Ua tsis tiav. Ceramic Toilets muaj 12.4% Ua tsis tiav, Tsis Sib cuag Spout muaj 32.9% Ua tsis tiav.

Lub Plaub Hlis 19, the General Administration of Market Supervision and Administration informed the 2021 national supervision and sampling of plumbing and sanitary ware product quality. The sampling of 988 enterprises produced 1033 batches of plumbing and sanitary products, koom nrog ceramic toilets, intelligent toilets, non-contact spout, ceramic piece sealing spout, shower, bathroom furniture, household stainless steel sinks and other seven products. One batch of the products was suspected to be counterfeit, and the inspected unit was Chaozhou Chaoan District Vijana Sanitary Ware Co. They were labeled as the M031-3 jet siphon toilet of Fujian Over River Dragon Sanitary Ware Co. They have been referred to the local market supervision department of the enterprise. The inspection found that 157 batches of products failed, and the sampling failure rate is 15.2%.

From this follow-up sampling to the last unqualified enterprises have 75, there are 21 enterprises in this sampling is still unqualified, thiab 54 enterprises qualified. From the sampling of industrial clusters of such products, tag nrho ntawm 506 batches of products produced by enterprises in Guangdong Province were sampled and 65 batches were found to be unqualified, with a sampling failure rate of 12.8%. From the sampling of 261 batches of products produced by enterprises in Fujian Province, 43 batches were found to be unqualified, with a sampling failure rate of 16.5%. From the sampling of 129 batches of products produced by enterprises in Zhejiang Province, 33 batches of which were unqualified, and the sampling failure rate was 25.6%. The specific sampling situation of each product is as follows.

Ceramic bidet

The sampling failure rate of 12.4%

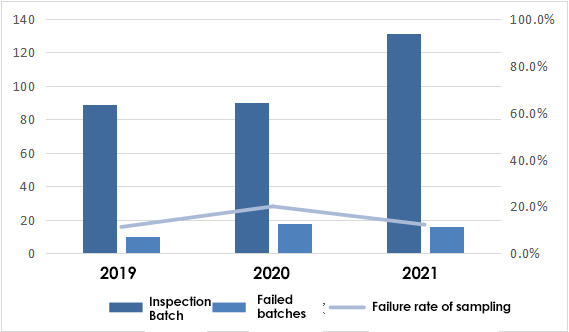

The sampling of 257 enterprises in 13 provinces (cities) produced 259 batch ntawm cov khoom, of which 32 batches are unqualified, and the sampling failure rate is 12.4%. This is a decline of 1.6 percentage points from the last sampling. The sampling failure rate of the product in the past three years were 13.4%, 14.0%, 12.4%.

The sampling focused on the toilet water consumption, discharge function, sewage replacement function, safe water level, toilet water efficiency level, toilet water efficiency limit value, inlet valve sealing, inlet valve pressure resistance, anti-siphon function and other 20 items were tested. Unqualified items are related to the toilet water consumption, water seal depth, toilet water seal surface size, washing function, water seal back to the function, safe water level, toilet water efficiency level, toilet water efficiency limit value, inlet valve CL mark, water tank safe water level and other 10 items. By the technical institutions, the main reason for the failure of ceramic toilet products: Ua ntej, China’s sanitary ceramics industry is dominated by small and medium-sized enterprises. Part of the small and micro-enterprise production automation is not high, so the quality of products is not stable. Second, some manufacturers are not strict quality control, and did not follow the standard requirements for the purchase of components and factory inspection.

The sampling inspection was conducted in Guangdong Province, Henan Province, Fujian Province and other industrial clusters of production enterprises. Ntawm lawv, 185 batches of products produced by enterprises in Guangdong Province were sampled and inspected, with a sampling failure rate of 15.1%. They also sampled and tested 22 batches of products produced by enterprises in Henan Province, with a sampling failure rate of 4.5%. They sampled and tested 21 batches of products produced by enterprises in Fujian Province, with a sampling failure rate of 4.8%.

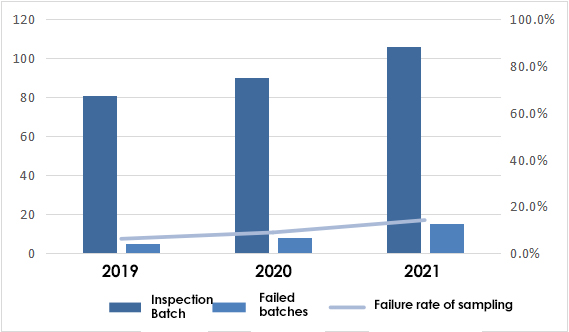

Intelligent toilet

The sampling failure rate of 8.5%

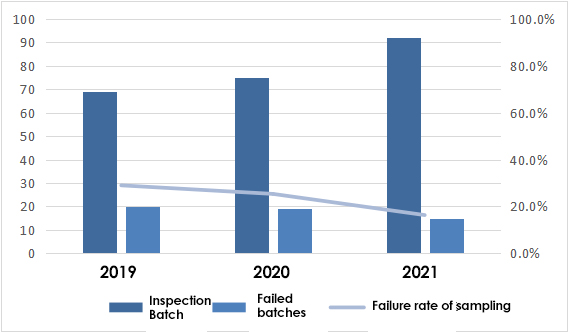

The sampling is the circulation of sampling. They sampled 106 batches of products produced by 68 enterprises in 10 provinces (cities), thiab pom tias 9 batches were unqualified, with a sampling failure rate of 8.5%. The rate of failure for the last three sampling inspections of the product was 2.7%, 3.8% thiab 8.5% respectively.

The sampling focused on the water temperature characteristics, nozzle self-cleaning, sitting ring heating function, the protection of touch and live parts, heat, internal wiring and other 41 items were tested. Failed projects involve the input power and current, protection of touch and live parts, qauv, grounding measures. After analysis by technical institutions, the main reasons for the failure of intelligent toilet products are: Ua ntej, the product structure is unreasonably designed to lead to the risk of use. Second, the intelligent toilet manufacturers are mostly small and micro enterprises, insufficient investment in research and development, limited quality management level, and the quality of products is not guaranteed.

The sample inspection was carried out in Guangdong Province, Zhejiang Province, Fujian Province and other industrial clusters of production enterprises. Ntawm lawv, they sampled and tested 46 batches of products produced by enterprises from Guangdong Province, with a sampling failure rate of 10.9%. They also sampled and tested 21 batches of products from enterprises in Zhejiang Province, with a sampling failure rate of 4.8%, and they sampled and tested 14 batches of products from enterprises in Fujian Province, with a sampling failure rate of 21.4%.

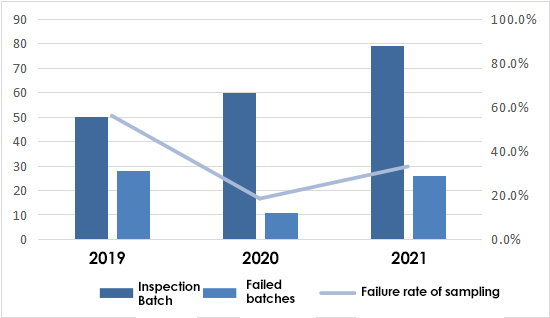

Non-contact spout

The sampling failure rate of 32.9%

The sampling of 79 batches of products are produced by 79 enterprises in 10 provinces (cities). They found 26 batches of unqualified, with a sampling failure rate of 32.9%. This is 14.6 percentage points higher than the last sampling. The sampling failure rate of the product in the past three years was 56.0%, 18.3% thiab 32.9%.

The sampling focused on the appearance of quality, safety performance, sealing performance, strength performance, control distance, energy consumption of the whole machine, power failure protection, water strike performance, water efficiency level of the spout, water flow, flow uniformity, flow performance, electric shock protection and other 17 items were tested. In addition to strength performance, sealing performance, resistance to installation load, anti-electricity protection, safety performance, opening and closing time and other six projects, other projects were found to be unqualified. Ntawm lawv, 15 batches of products were found to be unqualified flow uniformity project, 14 batches of products failed the water impact performance project. After analysis by technical institutions, the main reasons for the product failed: Ua ntej, some manufacturers are not officially implemented on January 1, 2021, based on the mandatory national standard GB 25501-2019 “water spout water efficiency limits and water efficiency levels” for production. Second, some enterprises are not strict internal quality management, and did not carry out effective factory inspection.

They sampled the production enterprises in Guangdong Province, Fujian Province, Zhejiang Province and other industrial clusters. Ntawm lawv, they sampled and inspected 27 batches of products produced by enterprises from Guangdong Province, with a sampling failure rate of 11.1%. They sampled and inspected 20 batches of products from enterprises in Fujian Province, with a sampling failure rate of 35.0%. They sampled and tested 15 batches of products from enterprises in Zhejiang Province, with a sampling failure rate of 66.7%.

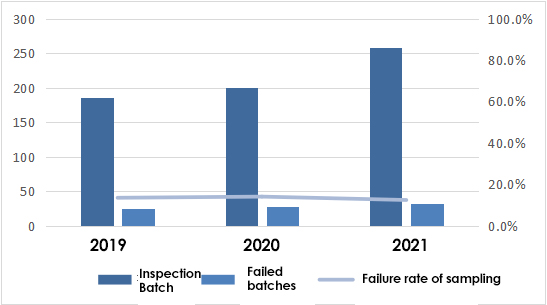

Ceramic piece sealing spout

The sampling failure rate of 16.9%

They sampled 260 batches of products produced by 256 enterprises in 11 provinces (cities), thiab pom tias 44 batches failed, with a sampling failure rate of 16.9%. This is 0.7 percentage points higher than the last sampling. The sampling failure rate of the product in the past three years were 13.1%, 16.2%, 16.9%.

The sampling focused on the accuracy of the pipe thread, hot and cold water sign, metal contaminant precipitation, water pressure mechanical properties, sealing performance, flow, surface corrosion resistance, flow uniformity, water efficiency level of the spout and other nine items were tested. In addition to the mechanical properties of water pressure resistance, sealing performance and other 2 projects, other projects were found to be unqualified. Ntawm lawv, they found that 19 batches of products failed the accuracy of the pipe thread project, 16 batches of products failed the flow uniformity project, 15 batches of products failed the surface corrosion resistance project. After analysis by technical institutions, the main reason for the failure of ceramic chip seal spout products is that the products are manufactured by small and micro enterprises. They are not strict quality control of outsourced raw materials and accessories, or their plating process has problems.

They have sampled the production enterprises in Fujian Province, Guangdong xeev, Zhejiang Province and other industrial clusters. Ntawm lawv, they sampled and inspected 119 batches of products from enterprises in Fujian Province, with a sampling failure rate of 21.8%. They sampled and inspected 92 batches of products from enterprises in Guangdong Province, with a sampling failure rate of 10.9%. They also sampled and tested 31 batches of products from enterprises in Zhejiang Province, with a sampling failure rate of 19.4%.

Showerhead

The sampling failure rate of 12.2%

They sampled 131 batches of products produced by 131 enterprises in six provinces (cities), and found 16 batches failed, the sampling failure rate of 12.2%. This is 7.8 percentage points lower than the last sampling. The sampling failure rate of the product in the past three years were 11.2%, 20.0%, 12.2%.

The sampling focused on the accuracy of the pipe thread, safety performance, emergency cold and heat resistance, corrosion resistance, sealing performance, mechanical strength, flow, overall tensile performance, temperature drop, handheld shower anti-siphon performance and other 10 items were tested. Failed items are related to the accuracy of the pipe thread, corrosion resistance, flow, hand-held shower anti-siphon performance. Analysis by technical institutions, shower products failed mainly because: Ua ntej, in the processing and manufacturing process, the enterprise’s thread processing accuracy is not enough, and the surface plating process is not good, or not supporting the anti-siphon device. Second, enterprises do not understand the product standards, not supporting the installation of water-saving tablets, which led to a large flow. The sampling inspection was carried out in Fujian Province, Guangdong xeev, Zhejiang Province and other industrial clusters of production enterprises. Ntawm lawv, they sampled and inspected 59 batches of products produced by enterprises from Fujian Province, with a sampling failure rate of 5.1%. They sampled and inspected 44 batches of products from enterprises in Guangdong Province, with a sampling failure rate of 4.5%. They also sampled and tested 25 batches of products from enterprises in Zhejiang Province, with a sampling failure rate of 44.0%.

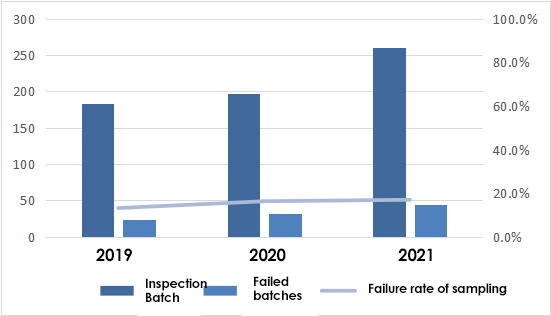

Bathroom furniture

The sampling failure rate of 14.2%

They sampled 106 batches of products produced by 106 enterprises in 9 provinces (cities), thiab pom tias 15 batches failed, with a sampling failure rate of 14.2%, nce 5.3 percentage points from the last sampling. The sampling failure rate of the product in the past three years were 6.2%, 8.9%, 14.2%.

The focus of the sampling counters on the physical and chemical properties of the counter surface of the basin, the physical and chemical properties of the wooden parts of the surface coating, soft and hard cover physical and chemical properties, metal surface coating physical and chemical properties, metal plating layer salt spray resistance, product water resistance, floor counter surface vertical impact, hanging cabinets (shelves) limit strength, wood products harmful substances limit, product radioactivity and other 10 categories of 24 items were tested. Failed projects involve the physical and chemical properties of the counter surface of the basin, the physical and chemical properties of the surface paint film of wooden parts, wood products harmful substances limit. After analysis by technical institutions, the main reason for the failure of bathroom furniture products is the use of inferior raw materials to reduce costs, or uneven coating of paint film.

They have sampled the Guangdong Province, Zhejiang Province, Fujian Province, Henan Province and other industrial clusters of production enterprises. Ntawm lawv, they sampled and inspected 56 batches of products produced by enterprises from Guangdong Province, with a sampling failure rate of 12.5%. They sampled and tested 23 batches of products produced by enterprises from Zhejiang Province, with a sampling failure rate of 8.7%. They also sampled and tested 10 batches of products from enterprises in Fujian Province, with a sampling failure rate of 20.0%. They also sampled and tested 9 batches of products from enterprises in Henan Province, with a sampling failure rate of 22.2%.

Household stainless steel sink

The sampling failure rate of 16.3%

They sampled six provinces (cities) 91 enterprises produced 92 batch ntawm cov khoom, thiab pom tias 15 batches failed, with a sampling failure rate of 16.3%. This is 9 percentage points lower than the last sampling. In the past three years, the sampling failure rate of the product was 29.0%, 25.3%, 16.3%.

The sampling focused on the drain wall thickness, drainage mechanism drainage time, drainage mechanism sealing performance, bearing performance and other 11 items were inspected. Failed items involve the use of overflow parts performance, drainage mechanism wall thickness, material chemical composition (nickel, chromium). Ntawm lawv, 13 batches of products were found to be unqualified for the drainage mechanism wall thickness project. The project in two consecutive years of sampling were found to be more prominent problems. After analysis by technical institutions, the main reason for the failure of household stainless steel sink products: Ua ntej, the size of the product overflow design is small or overflow structure is unreasonable, resulting in poor overflow capacity of the sink. Second, companies choose thinner drainage mechanism components to reduce production costs. This leads to the unqualified wall thickness of the drainage mechanism. Third, enterprises use low corrosion resistance of stainless steel materials for production and processing.

The sampling inspection was conducted in Guangdong Province, Fujian Province, Zhejiang Province and other industrial clusters of production enterprises, of which 56 batches of products produced by enterprises from Guangdong Province were sampled and inspected, and the sampling failure rate was 17.9%. They sampled and tested 18 batches of products produced by enterprises from Fujian Province, with a sampling failure rate of 5.6%. They also sampled and tested 9 batches of products produced by enterprises from Zhejiang Province, with a sampling failure rate of 33.3%.

iVIGA Kais Factory Supplier

iVIGA Kais Factory Supplier