Original Shi Yangyan Kitchen And Bathroom Information

Im März 28, Huida Smart Home (Chongqing) Co., GmbH. held the first phase of the production ceremony. After 39 years of precipitation, the top information technology team and ceramic equipment team work together to build, Huida 5G + digital intelligence factory debut to the media, industry and the public, kitchen and bathroom information President Yu Zhenrong and other invited to attend.

Huida Group President Wang Yanqing

The intelligent sanitary ceramic production line is designed independently by Huida Sanitary Ware, which is built according to the international Industry 4.0 standard, and the numerical control rate of key production processes reaches 100%, creating a new benchmark for the industry automation and intelligent ceramic product production line.

Industrial Internet of things into the intelligent factory

A new factory, from the ceiling of the factory, to the layout of the production line; from the setting of the gate, to the logistics of access channels; from the design of human access, to the trajectory of machine action; from automated equipment to intelligent equipment to intelligent workshop, a standard Industry 4.0 standard production plant, it needs to think about the operation logic, operation and production process from the factory level of the whole picture. With the help of plant layout and MES management system, Huida Digital Intelligence Factory models the material flow of processes at all levels, so as to achieve plant-level optimization, and then complete networking, automation and intelligence.

MES not only provides support for data collection, information flow and process coordination, but also provides support for the improvement and enhancement of manufacturing process technology. The 5G+ system digital kanban designed independently by Huida Digital Intelligence Factory monitors the production capacity, quality of each process, inventory, workshop work-in-progress, kiln situation (temperature, products, usw.), and temperature and humidity in the plant in real time, so that the whole production can be seen at a glance.

Gleichzeitig, seamless collaboration and intelligent scheduling are realized through intelligent high-pressure grouting system, robot repairing, intelligent drying, intelligent handling and packing robot, intelligent three-dimensional warehouse, intelligent loading and unloading kiln, usw. By identifying product models through industrial cameras, and with the help of “one product, one code” independently developed by Huida, the machine automatically selects suitable packaging materials and performs different packaging processes according to different product models. And through intelligent palletizing robot and AGV forklift, using wireless PLC communication, realize wireless docking. It is accompanied by the whole production process and can trace any part of the product (including raw material, operating machine, operator, process, production time and date, process parameters, usw.) through the QR code, which greatly improves the production efficiency.

The most valuable core “algorithm”: industry experience and process techniques

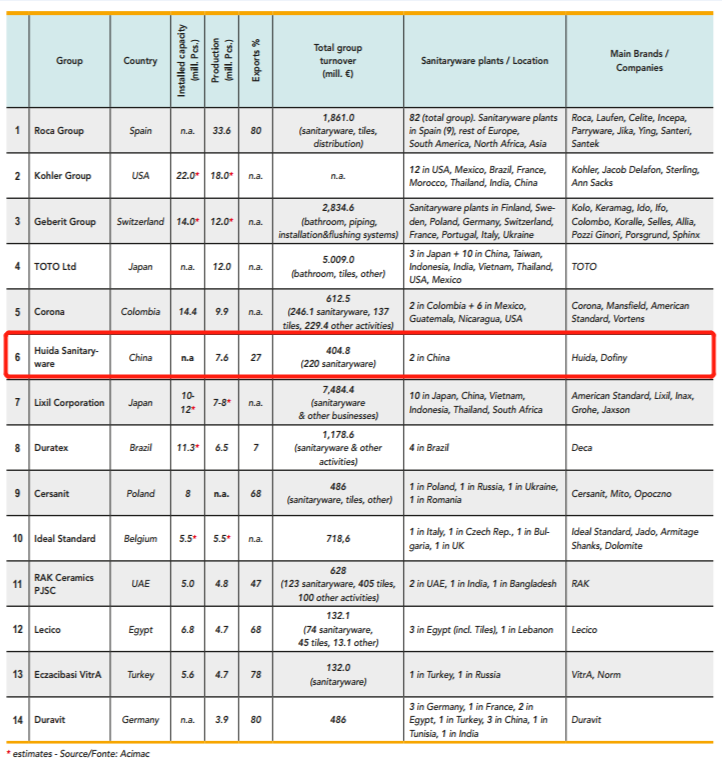

Derzeit, the world’s major sanitary ware players are in the production base for the global distribution, looking for the best manufacturing strategy. Yin Kang, executive president of Huida Sanitary Ware, pointed out that Huida 5G digital intelligence factory, so that the ceramic manufacturing has entered a new era. After nearly 40 years of development, it has now become an important enterprise in the global sanitary ware market. Huida always insists on walking on two legs, actively exploring the international market while focusing on the development of the domestic market.

The production of Huida Chongqing 5G Digital Intelligence Intelligent Factory will become the second headquarters of Huida in the southwest and even the south, building the core competitiveness of the national market while radiating to countries along the Belt and Road. The new development pattern of domestic and international double circulation is promoted by each other, mainly by domestic large circulation.

Huida’s large-scale production capacity and delivery capability, channel diversification and specialized channel direction will provide Huida’s retail, home improvement and engineering customers with more market competitive products and better delivery and service capability. In the list of 2020 global bathroom market players selected by the foreign media “Ceramics World”, Huida bathroom ranked sixth, becoming the only Chinese bathroom brand selected for the list.

As the first factory awarded as “5G+Industrial Internet Innovation Demonstration Base”, accelerating the integration of quality data, progress data, real-time equipment status parameters and processes, and deepening engineering processes will become an important goal of the next digital intelligent factory.

Wang Hui, general manager of Huida Intelligent Home (Chongqing) Co., GmbH. said that the system of design, equipment matching, and the articulation of each process are continuously optimized every year.

Derzeit, this intelligent production line will continue to refine and deepen the intelligence, in order to achieve the ultimate goal of 1+1=3. Now we talk about lean management, how to improve on the basis of intelligent production line. A teacher and a newcomer to operate the equipment, the quality of the tasks completed are also different. The use of the teacher’s experience, in-depth algorithms, digital talent comes to realize the progression of intelligent manufacturing. For the upgrade of Huida’s type of upscale factories, making full use of industry experience and process techniques is the most valuable core “algorithm”.

Kitchen and bathroom information President Yu Zhenrong (links) Huida Group President Wang Yanqing (center) Foshan Ceramic Industry Association Secretary-General Yin Hong (Rechts)

Related data: Huida bathroom Rongchang production base covers an area of 748 acres, with a total planned investment of 1.5 Milliarden Yuan, in three phases of construction, is expected to be completed in 2024. Darunter, the first phase of the project investment amounted to 450 Million.

Lieferant der iVIGA-Wasserhahnfabrik

Lieferant der iVIGA-Wasserhahnfabrik